➤ The Complexity of global supply chain is inevitable, however, developing and putting in place the right strategies is the key to overcoming those challenges.

➤ Chools competent team of consultants will guide you in selecting and executing the effective strategies that will drive your organization Sales revenue and Market Share Growth, Productivity, Excellence and Resilience.

➤ Following our Capability and Impact Assessments integrated with SWOT and PEST Analysis, we form your Y-Chart including your SMART goals to implement the Seven best In class supply chain strategies.

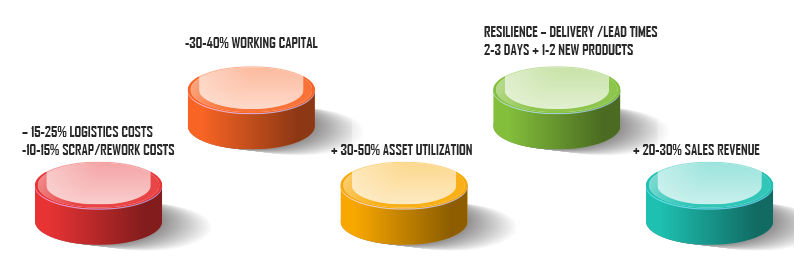

➤ Tracking the gains our Clients captured executing the 7- Best in Class supply chain strategies against companies that did not implement a methodological strategic way to drive their supply chain operations- The following was achieved

Strategy # 1: Embrace a business planning operating Model that is driven by real time Market Demand ( AI and IoT).

Strategy # 2: Develop a resilient organization reacting with agility to market demand in integrated planning and production.

Strategy # 3: Embrace Innovation and Design Methodologies to optimize Products and Processes: Manufacturing- Supply and Sustainability (Design thinking, DFSS).

Strategy # 4: Align all business goals by integrating Supply Chain, Sales, Corporate business planning and operations planning (S&OP and SC control tower).

Strategy # 5: Incorporate Environmental and Social Sustainability in Supply chain Operations (Corporate social responsibility, Carbon Foot prints, Energy usage etc.)

Strategy # 6: Adopt technologies (Data base Networks, Enterprise Resource Planning, and Artificial intelligence, SC control tower) to ensure predictable operations.

Strategy # 7: Establishing a supplier partnership relationship.